Safe with CEE It is always the same image in each campsite or motorhome area: no sooner has a caravan or motorhome reached the location allocated to it than the crew jumps out of the vehicle. After a quick search in the gas box or an outside storage compartment, the cable drum and the blue CEE plug are on the floor. Then the CEE plug is quickly plugged into the exterior pocket of the vehicle and connected to the cable drum. After unwinding the cable drum, the plug is inserted into the power column. And the vehicle’s electrical devices already work with electricity from the campsite or pitch. Besides the robustness and protection against dust and moisture, there are several other reasons for using CEE plugs. As we have already mentioned, it is impossible to connect a CEE plug “incorrectly.” In addition, the connections are consistently designed for 16 amps. Many campsites often have a 4, 6, or 10 amp low fuse power supply. Your kettle or hairdryer can quickly blow your location fuse. You can also use adapter cables that you connect via an extension cable. These are available on cable drums in various lengths. However, when using the cable, unwind it completely from the drum to prevent heat build-up. If you secure the connections with suitable rain and dirt safety boxes, nothing can go wrong. HOW DOES IT WORK WITH THE ELECTRICITY FROM THE CAMPSITE? Once there was a bucket of cold water next to the trailer for chilling beer. Today there is an electric cooker. Electric power, which supplies the energy necessary for recreational vehicles, is now the norm. After all, the coffee machine, refrigerator, and lighting should contribute to the usual comfort of camping trips. In addition, the vehicle battery or that of the cell phone, tablet, or camera needs their juice for the next use. Your motorhome or caravan is fitted with a CEE plug socket, which is housed in a box located in the outer wall of the vehicle. Inside, the cable is fused and goes to electrical devices and 230-volt outlets in your vehicle. If you now open the flap, you will discover the three pins of the CEE adapter. The CEE connector of your power cable is plugged in here. Directly connect the other end to the power column of your parking space, and your vehicle will already have 230 volts. You cannot avoid buying a CEE adapter, whether with a tent, caravan, or motorhome, camping. You need the CEE plug and an extension cord if you want to be supplied with electricity at your campsite.

INGENIOUS CONNECTIONS: Quickly and easily install the plugs and sockets using a minimum of tools

Clever Energy Distribution with Alexander & Poole Around-the-clock production: the conveyor belts and machines of a manufacturing plant hardly ever stand still. To prevent downtimes, they need to be consistently and reliably supplied with power and data. We can help! You’ll find a variety of tried-and- proven plugs and sockets in our product range. Combination units are available for wall mounting, suspending from the ceiling, and carrying around. For data transmission, we offer a wide range of solutions including industrial network distributors, data port sockets, and compact network distributors. Thanks to clever features, it’s easy for you to install our solutions and safely and reliably use them for years. Our CEE plugs and sockets boast an ergonomically optimised design, nubbed grip zoness, a rubberised nubbed cable gland, an easy-open hinged cover, and locking sliders to ensure that CEE plugs and connectors are easy to grip, rest perfectly in the hand without slipping, even when moist or wet, and have a lifetime of several thousand mating cycles. Our plugs and sockets are made of robust, durable materials. The plugs and connectors feature ingress protection, this means that they are optimally protected from dust and water. Featuring highly heat resistant contact carrier and are optionally available with nickel-plated contacts. The plugs also have nickel-plated contacts.

Waterproof Industrial Socket. What is it?

The industrial sockets are designed to be used in many environments according to the application where the industrial socket is needed. The secure reason is one of the top priorities when you choose an industrial socket. Especially when the products are used in the place of heavy dust and wet. A waterproof industrial socket is invented driven by this requirement. Not all industrial sockets are waterproof. No matter which manufacturer produces it, they have the waterproof socket something in common. The housing material: for a water-resistant industrial socket, the shell is made by PP (polypropylene) / PA (Nylon, Polyamide). These materials have good stability to water. Besides, they have a wide temperature range of tolerance from -40°C to 90°C. The inner parts: almost all the plastic inner parts are made by flameproof PA material. Actually, for a waterproof industrial socket, it is also a flameproof product. For a waterproof industrial socket, you will find one of these marks on the shell IP44, IP55, or IP67. What is that? These marks are called IP degree, an abbreviation for Ingress Protection rating. The IP degree is recommended by IEC. It has as many as 9 categories of protection rating, using for defining how an electric device is water and dust resistant. In different application environments, the rating level will be different. The correct writing of a IP degree is IPXX, take IP67 for example. The first number “6” refers to the dust protection rating. From IEC (cee), there are 7 categories to describe dustproof rating. They are numbers from 0 to 6. The 6 is the highest rating, meaning that the dust is completely prevented from entering into the device. The second number “7” refers to the water resistance capability. Similar to the dustproof grades, there are 9 waterproof degrees, showing with numbers from 0 to 8. The 7 is the second-highest protection rating, meaning that the socket can still work safely when it is underwater (no deeper than 1 meter) in a short time. For the waterproof industrial socket, there are 3 grades which are the most commonly seen: IP44, IP55, IP67.

CEE Overview

Industrial products are different from the ones found in your household. They have the ability to support higher currents and voltages. This is why industrial plugs and sockets are suitable for use in polyphase systems with high currents. They are also ideal for use in scenarios where you need protection from environmental hazards. Industrial outlets have several important supporting features. They have weatherproof covers or waterproof sleeves. Some industrial sockets come interlocked with a switch. This switch will help from accidentally disconnecting when connected to an energized plug. Besides, some industrial connectors are approved for use in “high-risk” areas, for example, in places like petrochemical plants and coal mines. These places have flammable gases, which can pose a threat. The CEE Form, or the CEEForm, stands for Certification of Electrotechnical Equipment. This is a certificate issued for electrical products, and useful to trade electrical products globally. The best-known CEE standards are the CEE 7, CEE 13, CEE 17, and CEE 22. 1. The CEE 7 is the standard used for household plugs and sockets. 2. The CEE 13 is the standard used for cables and cords. 3 The CEE17 is the standard used for industrial plugs and sockets. Today, the CEE 17 is known as the IEC 60309 (formerly called the IEC 309). This is an international standard governed by the International Electrotechnical Commission (IEC). The IEC 60309 regulates industrial plugs, sockets, outlets, and couplers. In Europe, industrial connectors are made to the IEC 60309 standard. Various other criteria based on IEC 60309 include the BS EN 60309-2 and the BS 4343. Usage scenarios for different industrial plug and socket models: Industrial plug: This is similar to the plugs in the electrical equipment of our households. Used for any type of sockets. Industrial Connector: This is a movable socket used in extended power supplies. They are suitable for portable use too. Wall-Mounted Industrial Socket: This is mounted on walls and equipment surfaces. The wires that connect to this socket are on the wall and the device’s body. Panel Mounted Industrial Socket: Typically used for cabinets or equipment. The user will fix the main body of this product on the surface. And the wiring inside the equipment or panel is not visible. Angled Mounted Industrial Socket: This socket has a similar function to the panel-mounted ones. But the significant difference is the socket and the panel of the concealed inclined seat are angled. It does not have a typical 90-degree angle. Reverse Industrial Plug: This is a fixed plug. You can expect only connectors to work with it. This reverse plug is divided into the panel and wall-mounted plugs. The installation form of the plug is similar to the one on the socket.

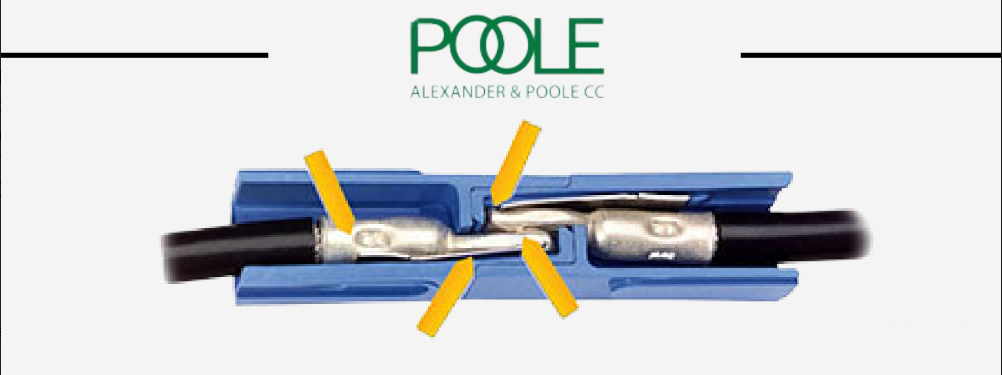

3 Reasons Genuine Anderson Connectors are First Choice

Have you been wondering if Anderson Power Products (APP) connectors should be mated with similar connectors from other manufacturers? Wouldn’t it be easier if you could mate all of the connectors that you have? This would be an ideal situation but there are three main reasons why this can’t be true. Now, before we get started let’s understand the key component… flat-wiping contact. This contact system has been so popular that other manufactures also copied Anderson’s original designs. The flat-wiping contact technology can be found in a lot of the APP connectors like SB and Powerpole. Component Standardisation The vast majority of component standardisation efforts are focused on AC power such as The National Electrical Manufacturers Association (NEMA) or The International Electrotechnical Commission (IEC) wall outlets and plugs. AC power is primarily used to distribute electrical power in commercial and residential facilities that require standards for fire prevention and building code standards. Standardisation is necessary to ensure consistency among all manufacturers. Anderson connectors using flat-wiping contact technology; (Powerpole, SB, SBS, SBE, SBX, etc.) are not manufactured to a dimensional or performance normative standard. Other manufacturers have simply attempted to reverse engineer the original Anderson design. The performance of these copies varies significantly in absence of the APP expertise from invention of the flat-wiping technology. Manufacturing Differences Copies of APP original designs often do not use the same raw materials, manufacturing, or assembly techniques. This directly results in performance differences and lack of compatibility. Every manufacturer also makes ongoing adjustments to product design or manufacturing methods which are only tested for reverse compatibility with their own products. As a result, any basis of compatibility established cannot be assured going forward. Further, the quality control differences can vary significantly from one manufacturer to the next. Safety Agency Certifications Non-standardised components from different manufacturers do not maintain their certifications when mated with a product from another manufacturer. The certification is based on a mated set of product from the same manufacturer. In contrast, certification of standardised components like IEC or NEMA connectors are established based on compliance of only one half of the connection to allow mixing between different manufacturers. This is because the standard defines the parameters of both sides of the connection which all suppliers manufacture to. The three above reasons highlight why Anderson connectors are not compatible with copies from other manufacturers: Component Standardisation, Manufacturing Differences, and Safety Agency Certifications.

IP67 PLUG STRUCTURE

Talking about waterproof industrial socket and plug, there are two main categories for sale: IP44 and IP67. Besides the different grades of waterproof capability, another minor difference between the two types lies in the outer dimension, the design of the pin, the slot diameter. The IP67 plug consists of shell, ring, seal, pin, grip, cable clamp, cable seal, screw, etc. the structure diagram of an IP67 industrial plug. For IP67 and IP44 industrial socket and plug, they have basically the same structure, except for the shell, the section rind, and the sealing ring. The shell is designed as protection and enclosure for the pins inside. It is connected with the handler. The most important property for the shell is its waterproof performance. The handler, which is connected with the shell, is the other shell part for an industrial plug. The surface is designed with non-slip stripes. At the tail end, there is a cable entry. According to the IP67 standard, the cable entry is reinforced with thread cover, metal washer, and rubber sealing ring. It is the key part of an IP67 industrial plug. The lock ring can be freely rotating around the shell while the fixing tooth protects the lock ring from falling off. The sealing ring plays the main role in water protection. Normally it is made of rubber or other elastic material. In an IP67 industrial plug, three sealing rings are used: (a) the sealing ring used between the socket and plug insertion surface. (b) the sealing ring used between the shell and the handler. (c) the sealing ring used for the cable.

Your ‘How To’ Guide

Proper crimping and cleaning of the wire is essential for optimizing connector service. A proper crimp that is performed on oxidized wire may have high resistance and could result in excess heat. Cutting back cable to a non-oxidized area and / or cleaning the wire with a wire brush or 3M Scotch Bright is recommended. Stripping Cable Insulation: Problems with cable harness and connector systems often begin with improper or accidental cutting of wire strands while stripping cable insulation. Each strand is important, and all of them must be included in the contact barrel to avoid unnecessary hot spots during operation. When removing insulation, position a sharp blade at a right angle and apply steady, controlled pressure, cutting only the cable insulation, not the copper wire. Strip cable to the proper length for the contact being crimped. Proper lengths are listed in the instruction sheet with each APP connector. Cleaning Copper Wire: Aged and badly tarnished copper should be thoroughly scraped with a stiff wire brush that penetrates the entire bundle cleaning every strand. The wires will then be ready for insertion into the contact barrel when they are brushed to their original bright copper finish. Contact barrels are lined with silver or tin plating to assure consistent conductivity, which will be reduced if the barrel is crimped around aged or tarnished wire. Crimping The best preparation will be defeated if inadequate tools or improper crimping procedures are performed. Use an APP crimp tool. Make sure the stripped cable is inserted all the way into the barrel of the contact and that the contact point is centered in the crimp tool. A crimp tool will effectively compress the contact barrel tightly around the cable strands, allowing them to be pressed tightly against each other and against the inside wall of the contact barrel. When the crimp has been completed, check the appearance of the contact. A properly crimped contact barrel is compacted tightly with the outer strands. The outer strands on an improperly crimped barrel will be loose and will not have adequate clamping force. Test for low pull-out force. If the cable can be loosened, recrimp until it is tight. Soldering The alternative to crimping is to solder all cable strands within the contact barrel. When using an open flame, make sure that you are not in an area where explosive gasses are present. The right proportion of solder is essential if this procedure is employed. Use a quality 60/40 soldering in wire form with a rosin flux core. Cable strands should be separately fluxed with rosin paste, and the contact should be held in a vise with the barrel end facing up. Apply heat to the outside of the barrel while the solder flows in beside the wire strands. Contacts should never be forced into housing.

ALEXANDER & POOLE CONNECTORS – PRODUCT GUIDE

Anderson is a brand known for their quality connectors and providing superior strength and durability. In addition to Anderson’s line of SB Connectors, their Powerpole line is very popular. Like the SB Connectors, the Powerpole connectors are genderless and interchangeable. The main difference when it comes to the Powerpole line is allowing for custom multi-pole configurations. This allows the connectors to be more versatile and work in a wide variety of applications. For even more on why Anderson Powerpole connectors may be the products for you, read on! Powerpole Connector housings are available in 15-45, 75, 120, and 180 amp options. To clarify, Powerpole 15-45 all use the same type of housing, and the difference would be in the amperage of the contact. We will go into more detail on contacts in the next section. Like the Anderson SB series, the Powerpole line offers benefits such as an interchangeable, genderless design. Made out of a strong single piece of polycarbonate and color-coded housings, Anderson connectors make for a durable connection and easy connection. These accommodate smaller gauge sizes the SB connectors cannot. The Powerpole series is single-contact instead of dual contact which makes for a smaller housing as well as a different look. One major benefit of the Powerpole line is the stackable feature. This allows users to build custom multi-pole configurations for any specific application. When the 15- 45 amp connectors are stacked, they can be placed into an outer housing in order to hold the connection in place. The SB and Powerpole connectors share similar contacts. The contacts are silver plated and are self-cleaning. This allows for limited corrosion and a long life. The contacts added exclusively for Powerpole are the 15 and 30 amp contacts. As discussed earlier, there are to fit the smaller gauge applications and fit within the same 15-45 amp housing. Being spring loaded and contoured, the contacts are used for up to 600 volts continuous AC or DC operation. Overall, Anderson Powerpole Connectors are an industry standard for a secure and reliable connection. With the multi-pole configurations, these products are sure to fit your specific application. To see the completed assembly video of Anderson Powerpole connectors, click here. Best used in electrical equipment in commercial and industrial applications, the Anderson line is sure to please.

Advantagesof Anderson Connectors

At Alexander & Poole, we only stock genuine Anderson Power Products Connectors. APP Anderson Connectors are make a better connection, they’re more durable and will last much longer than cheaper brands. The Anderson Powerpole Connector facilitates a quick, easy and secure electrical connection. The connectors are moulded with dovetails so that the housings can be interlocked to form multiple connections. The housings can be interlocked as many times as needed and different colour Andersen housings can be utilised. The housings simply and quickly slide into place to create multiple connections. What are the advantages: High Current Systems – they are ideal for use with high current systems and have been designed to offer minimal contact resistance. High Durability – the durability and robust nature of these units allows for 10,000 mating cycles across their lifetime. They also demonstrate excellent resistance to chemicals such as solvents and hydro carbonsas Easy Quick Assembly – the genderless connection feature facilities quick and easy assembly and reduces inventory requirements. Finger Probe Safe – the housing has been designed to help prevent any accidental contact with live components – in compliance with the UL 1950 finger probe test. Colour Coded – the colour of the Anderson Power Connector designates the recommended application voltage as per industry standards. This safety feature helps prevent two different voltage colour housings from being connected and avoids the occurrence of a mismatch between power supplies/ electrical systems. We stock a range of Anderson Connector accessories. We stock brackets for mounting, and dust covers and protectors for keeping the connector clean and dry when not in use.